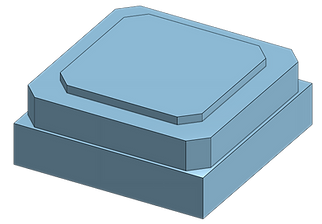

CNC Jewelry Box

The objective of this project was to introduce the class to the CNC and manual mill. I worked with a partner and we decided to keep our design simple to minimize manufacturing time. Both of us had experience with the manual mill going into the project but not with the CNC mill. We wanted to have as few tool changes as possible so we used a face mill to face our part and the rest of our design used a 1/4" end mill. Our operations went mostly according to plan with the exception of our facing being slightly off center. I was able to fix this problem by cleaning up our part on the manual mill after our CNC operations were complete.

Design Process

The two constraints of this project were the size of the block and a machining time of less than 20 minutes per side. We originally planned for our box to be made of aluminum however the CNC equipped with flood cooling was experiencing problems. With the intentions of minimizing machining time my partner and I created a very simple design with minimal tool changes. The original block was 3"x3"x1.25". One challenge of the project was for each partner to design one side of the box and coordinate the pieces fitting together. I designed the lid to the box and machined the base for my partner. She designed the base but handled the machining for my lid.

.png)

Jewelry Box Lid

Lid Drawing (click to expand)

Design for Manufacturing

To help reduce machining time our design only had one tool change. We started with a facing operation using a face mill and then moved on to the rest of the design using a 1/4" end mill. We chose to make our part slightly smaller than the stock size so that every surface could have a machined finish without excess labor on the manual mill. Our part after the CNC can be seen on the left. The facing operation did not go entirely according to plan and missed some material on the top surface. After the CNC operations were complete, I loaded the part into the Bridgeport and machined the top and bottom surfaces until the pedestal and top bits were gone.

Base before post processing

Base after manual mill and filing

Reflection and Teamwork

This section will be updated soon!