top of page

Black + Decker Cordless Drill Teardown

For this project, I chose to model a lot of small interior components of the drill. This project was highly enjoyable and I learned how to efficiently model pieces, a variety of ways to approach modeling, and what approaches suit me best. All pieces were designed in SolidWorks.

.png)

.png)

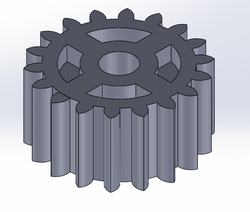

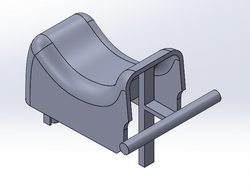

Modeling a variety of interior pieces meant that I made many simple pieces and a number of slightly more complex pieces. To the left are some of my favorites that I modeled.

I really enjoy figuring out how to approach different problems, and modeling so many different pieces gave me a lot of problems to think about.

On the top left is the bit holder, which I picked to include in my favorites because I enjoyed making the angled holes in the larger piece and constraining the assembly so the pieces move in and out as they do in the drill. I also picked the bit to include because I enjoyed making the Phillip's head and it fit with the bit holder.

I included some of the caps I made because I think the detail you can get from basic extrudes and cuts is incredible, and I also got better at adding threads to different items.

For this project, we also made a product decomposition table, and recorded our disassembly process. You can download the pdf here.

Tightener |  Carrier 1 |  Polymer Gear |

|---|---|---|

Metal Gear |  Trigger |  Gear + Carrier Assembly |

Motor |  Motor Cover |  Bit hh Ring |

Ball Bearing Ring |  Sungear |  Metal Top |

Snap Ring |  Ring |  Washer |

bottom of page