top of page

Physical Projects Overview

Laser Cutting

Laser Cutting

I have experience using a VLS 3.60 Laser Cutter and can export and convert files from AutoDesk Inventor or SolidWorks to the printer for laser cutting. Check out my Laser Cut Earrings page!

_JPG.jpg)

Sheet Metalworking

Sheet Metalworking

I have done sheet metal working including strain hardening, bending, shearing, and adding rivets to create a variety of projects. Different machines that were used to create the metal box on the left were a jump shear, table bender, 3-in-1 bender, English wheel, and a bead roller. We also used manual items such as hand punches, shears, and rivet guns. At the end of the lab, we were given metal scrap to experiment with and practiced using the 3-in-1 bender and and rivet guns. Check out my Sheet Metal Staircase and Sheet Metal Lamp!

Sand Casting

Sand Casting

Practiced sand casting using a bismuth-tin alloy. Created the mold using an acrylic pattern, and used a pin to create the sprue and the runner for the metal to flow through. After the casting, we could remove the sprue and file the edges of our part if we chose. Common issues encountered were not being able to get the sand out of the text in the acrylic and a lack of definition in the tusks. To counter this, we were given powder to coat our acrylic.

3D Printing

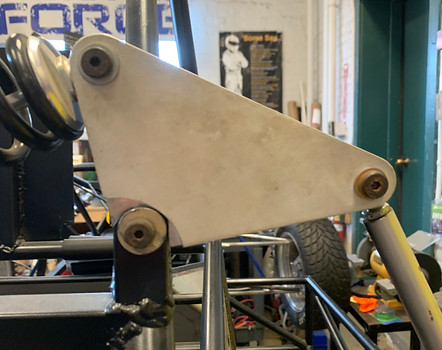

Designed a suspension piece (shown right) in SolidWorks to temporarily go on the Electric Racing car so that we could test the steering. The piece will ultimately be replaced with one that is metal (as seen below), however putting it on the car allows the wheels to rotate and turn more freely.

3D Printing

Soldering

Soldering

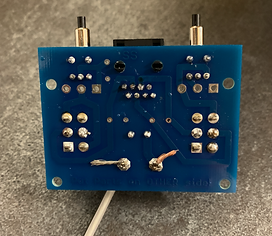

Helped to solder components to this circuit board that is a part of the sea perch being built for Tufts Robotics. More soldering can be seen on my PCB project page.

Water Jet

Water Jetting

Designed the chassis for a tank and used the water jet to cut our piece of sheetmetal. The water jet allowed for a precise design and placement of mounting holes, which was far more efficient than punching holes ourself. This design was later bent into shape using a table bender. The piece seen on the right is the base for my tank and car races robot!

Welding

I've learned MIG welding through the Electric Racing team as well as a fabrication class. The Tufts Electric Racing team welds when we need to attach new components to the frame of the car. For the fabrication class we practiced welding by creating a practice square and a hexagonal prism. On the left is an example of a practice fillet weld I did before welding the hexagon seen on the right. Check out my Welded Artwork!

Welding

bottom of page